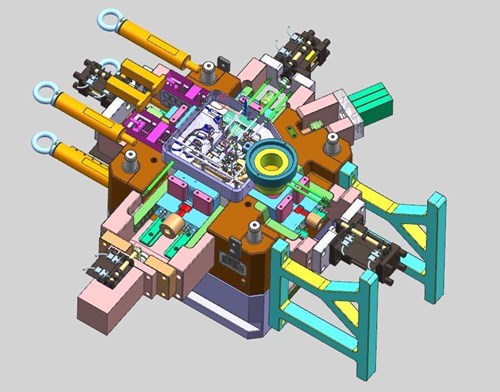

Mold R& D

Mold R& D for aluminum alloy casting

The Importance of Mold Design

Mold design is one of the most crucial steps in the process because the shape and attributes of the mold will directly affect the final product. The die casting procedure forces molten metal into molds using high pressure while it requires a mold with exact specifications to achieve the task.

Mold design affects the shape, configuration, quality, and uniformity of a product created through the die casting procedure. So the exact mold design can improve efficiency and production time.

Drawing Software

- 3D design software

- 2D design software

- CAD Systems: Cimatron,Solid Works, AutoCad / CADKey

- CAM Systems: Cimatron,Virtual Gibbs, Esprit

- Handling file formates: igs, stp, step, dxf, dwg, and any formates can be handled by above softwares

- Pro-E,UG

- Mold flow analysis of die casting mold(3D flow simulation)

PREVIOUS:Rapid Prototyping

NEXT:High Pressure Die casting